Dr Schar Industrial Bakery

Dr Schar opens its first US plant and chooses IPAS to design the dehumidi-fication and control system for their spiral coolers and freezers

Read Full Article: Download PDF ![]()

Background

Dr Schar owns and operates a 50,000 sq ft industrial bakery in Logan Township, NJ. As with all of Schar’s other global locations, this plant is a dedicated gluten-free facility and adheres to the highest quality stan-dards in the industry. One way they exceed these standards is through the use of spiral coolers and freezers that allow for precise humidity and tem-perature controls staged in a Clean Room 10,000 en-vironment. Historically, Schar addressed their cool-ing and dehumidification needs using solid desiccant systems which requires an increased cooling capacity and is more costly to build and operate.

Dr Schar owns and operates a 50,000 sq ft industrial bakery in Logan Township, NJ. As with all of Schar’s other global locations, this plant is a dedicated gluten-free facility and adheres to the highest quality stan-dards in the industry. One way they exceed these standards is through the use of spiral coolers and freezers that allow for precise humidity and tem-perature controls staged in a Clean Room 10,000 en-vironment. Historically, Schar addressed their cool-ing and dehumidification needs using solid desiccant systems which requires an increased cooling capacity and is more costly to build and operate.

Schar took a innovative approach to it’s new plant and integrated the air delivery systems with the op-eration of the spiral conveyors, requiring the design and installation of a custom control system capable of managing all operations in parallel.

Design Specifications

Spiral Cooler #1

- 68° F @ 50% RH with a tolerance of ± 5%

- Control dwell time on the spiral conveyors and fan speeds for different products

- Maintain Class 10,000 (ISO 7) clean room stan-dards

- Control multiple boxes and functions with one control panel / system

Spiral Cooler #2

- 50° F @ 50% RH with a tolerance of ± 5%

- Control dwell time on the spiral conveyors and fan speeds for different products

- Maintain Class 10,000 (ISO 7) clean room stan-dards

- Control multiple boxes and functions with one control panel / system

Solution

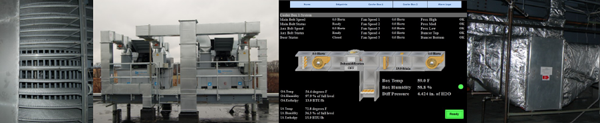

IPAS designed and installed a custom air delivery sys-tem using (2) Advantix DT3400/9 liquid desiccant units in conjunction with supplemental cooling and energy efficient HEPA filtration. IPAS partnered with Energy Efficient Technologies to design and install an open architecture control system to ensure the inte-gration and functionality of all operations. Systems and settings can be controlled from the touch screen located at the box, a laptop or smartphone.

Benefits

- Precise control of system functionality

- Low energy usage

- Decreased capital expenditure

- Reduced maintenance

- Adaptability and flexibility to add additional com-ponents to the control system

OTHER SOLUTIONS IN ACTION